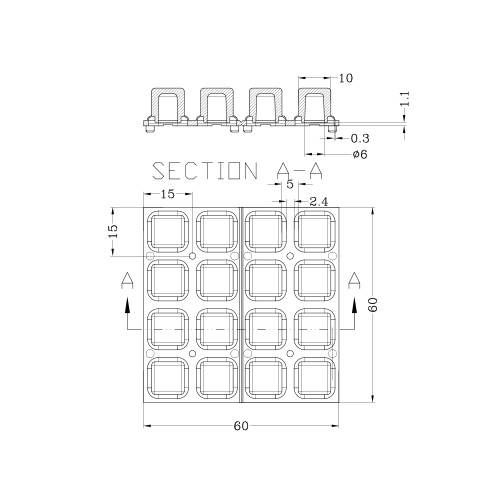

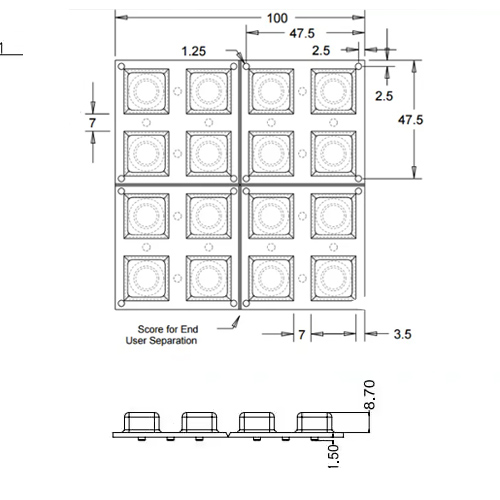

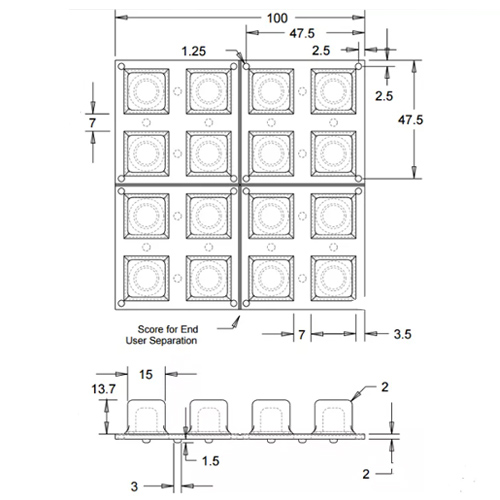

There are generally three types of commonly used specifications. The first type has a length and width of 60x60 mm and a height of 10mm. The second and third types have overall dimensions of 100x100 mm and a height of 8.7mm and 13.7mm respectively.

60mmx60mmx10mm

100mmx100mmx8.7mm

100mmx100mmx13.7mm

4x4 Translucent Silicone Button Keypad's Design Considerations

Proper design of 4x4 Translucent silicone keys is key to achieving good backlighting and tactile feel. The following are important factors that engineers need to pay attention to when designing.

Key travel

Hardness

Contact force

Contact resistance

Driving force

Surface Technology

Keypad material

Advantages of Yuanyi’s 4x4 Translucent Silicone Buttons keypad

Perfect size maintains an excellent feel yet

Reliable and low-cost

It has a long service life and can be reused many times.

Very soft and stretchy.

Excellent thermal oxidation and chemical resistance.

Naturally resistant to vibration and water and dustproof.

Easy to clean and disinfect, it maintains performance in high-temperature applications and requires just a soapy wipe.

Features of 4x4 Translucent Silicone Button Keypad

A round ring conductive ink is printed on the back side of each button, contacting the exposed PCB traces to complete the circuit.

A single small hole in the bottom of the button accepts a 3mm or 5mm diameter tri-color LED to create the button interface of your choice.

Proper key travel design provides positive tactile feedback.

Screen printing on key tops for multiple appearance and aesthetic options and spray polyurethane for added durability.

Our 4x4 transparent silicone button keypads have very high design flexibility and can be split into different specifications of button keypads, namely 2x2, and 2x4.

Application of 4x4 Translucent Silicone Button Keypad

Music equipment

Electric toys and games

Medical equipment

Mechanical equipment

Remote control system

Communication device

Production Process of 4x4 Translucent Silicone Button Keypad

Step One: Use the right materials

To use suitable specifications of silicone rubber materials, conductive ink, and vulcanizing agents. The right hardness is key to soft silicone keys.

Step 2: Molding

After preparing the correct specifications of the silicone rubber material, use a specific mold and compression molding process to start production. Temperature, pressure, and vulcanization time are crucial to the quality of the silicone buttons keypad.

Step 3: Secondary vulcanization (Optional)

After high-temperature vulcanization, the product undergoes secondary vulcanization to remove residues and improve performance. The product is usually placed in a vertical oven and baked at 180-200°C for 2-4 hours.

Step 4: Surface treatment (Optional)

To meet the performance or appearance requirements of some customers for the surface of silicone buttons, different processes or methods are usually used to process the product's surface, such as silk screen printing, spray laser engraving, PU coating, matte smooth coating, etc.

Step 5: Trimming

To make the silicone buttons perfect, the excess burrs of the silicone buttons are usually trimmed manually. This is sometimes done using a punch press.

Step 6: Final inspection, packaging

All products will eventually undergo random inspection by our quality department. Unqualified products will be scrapped directly. Qualified products will enter our finished product warehouse before packaging.