IATF 16949:2016 & ISO9001:2015 Email: jazz@yuanyicommodity.com Tel: +86-15918732691 WhatsApp: +86-15918732691

Factory: Huangshan Yongrui BiotechnologyCo., Ltd.

Office: Guangzhou Yuanyi Commodity Co, Ltd.

ISO9001

- Home

- OEM/ODM Service

- Silicone baby products

- Silicone Bibs in Stock

- Silicone baby bowls in stock

- Silicone Baby Spoon in stock

- Collapsible Silicone Snack Cup in Stock

- Mother Care Products

- Baby feeding set

- Silicone Suction Plate

- Silicone Bibs

- Silicone Baby Bowls

- Silicone Teether & Pacifier

- Silicone Feeding Spoon & Fork

- Silicone Baby Led Weaning Tableware

- Custom Silicone baby Feeding Set

- Silicone kitchenware products

- Custom silicone rubber parts & accessories

- Rubber keypad customization solution

- Custom Silicone Pet Slow Food Bowl

- Silicone baby products

- Capability

- Resource

- Contact

Meeting demand for specific colors is critical to the successful launch of a brand for baby products. Our exceptional team can create specified colors for customers' preferences and use their exceptional color-matching technology to achieve accurate color matching and a wide range of high-quality baby products. Not only are these brightly colored silicone products resistant to fading over a longer period, but they also enhance visual appeal.

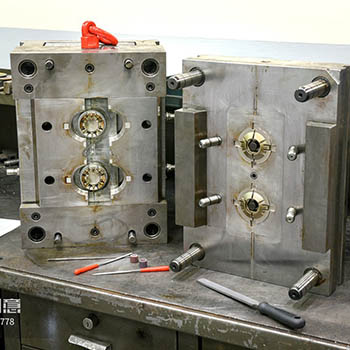

Meeting demand for specific colors is critical to the successful launch of a brand for baby products. Our exceptional team can create specified colors for customers' preferences and use their exceptional color-matching technology to achieve accurate color matching and a wide range of high-quality baby products. Not only are these brightly colored silicone products resistant to fading over a longer period, but they also enhance visual appeal. We offer the custom sizes you need, and custom baby products that fit your brand needs. To ensure the high specifications of each baby product, Yuanyi uses precise and durable molds.

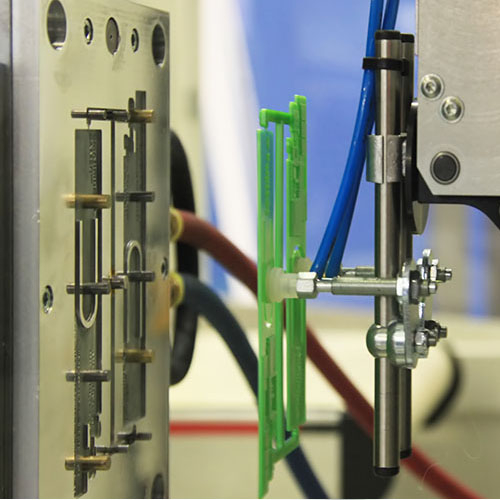

We offer the custom sizes you need, and custom baby products that fit your brand needs. To ensure the high specifications of each baby product, Yuanyi uses precise and durable molds. The design of the logo itself is crucial to the value and style of a baby product. Make your brand stand out by creating a single or multi-color logo for your baby products with many different customization methods. These methods are usually silk screen printing, laser engraving, pad printing, heat transfer printing, and engraving LOGO on the mold. We use advanced professional machines to add LOGO to your baby products to make them valuable and unique style.

The design of the logo itself is crucial to the value and style of a baby product. Make your brand stand out by creating a single or multi-color logo for your baby products with many different customization methods. These methods are usually silk screen printing, laser engraving, pad printing, heat transfer printing, and engraving LOGO on the mold. We use advanced professional machines to add LOGO to your baby products to make them valuable and unique style.