IATF 16949:2016 & ISO9001:2015 Email: jazz@yuanyicommodity.com Tel: +86-15918732691 WhatsApp: +86-15918732691

Factory: Huangshan Yongrui BiotechnologyCo., Ltd.

Office: Guangzhou Yuanyi Commodity Co, Ltd.

ISO9001

- Home

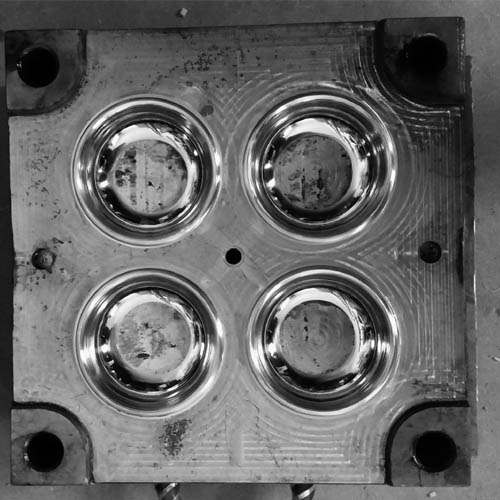

- OEM/ODM Service

- Silicone baby products

- Silicone Bibs in Stock

- Silicone baby bowls in stock

- Silicone Baby Spoon in stock

- Collapsible Silicone Snack Cup in Stock

- Mother Care Products

- Baby feeding set

- Silicone Suction Plate

- Silicone Bibs

- Silicone Baby Bowls

- Silicone Teether & Pacifier

- Silicone Feeding Spoon & Fork

- Silicone Baby Led Weaning Tableware

- Custom Silicone baby Feeding Set

- Silicone kitchenware products

- Custom silicone rubber parts & accessories

- Rubber keypad customization solution

- Custom Silicone Pet Slow Food Bowl

- Silicone baby products

- Capability

- Resource

- Contact