In designing the silicone rubber keypad's structure, due to the limitation of geometry and assembly structure or high appearance requirements, engineers need to make the thickness, width, gap, and other structures of the silicone rubber keypad as small as possible. And these minimum dimensions must follow certain specifications when designing. On the contrary, if the minimum size principle is not followed when designing the structure, the mold may not be opened, it may be easily damaged after opening, the service life may be short, or the product may not be completely removed from the mold after it is formed.

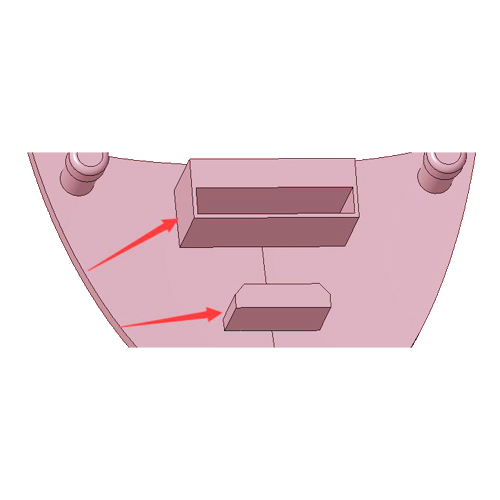

Minimum width of steps and ribs in silicone rubber keypads

Bosses and ribs usually refer to the protruding steps and ribs in the silicone rubber keypad. Generally speaking, these steps and ribs have the functions of positioning, supporting, sealing, waterproofing, etc. The higher their height, the larger the minimum width required.

When their height exceeds 1mm, the minimum width required is greater than 0.5mm. When the height is greater than 2mm, the minimum width is greater than 1mm. If the width is less than the design specification, some problems will arise, including mold difficulty, the product is prone to material shortage, cracking, and difficulty in demoulding.

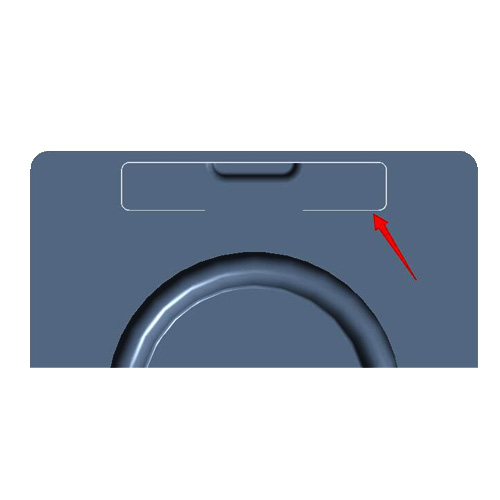

Minimum width of the gap on the silicone rubber keypad

Designing the structure of a silicone rubber keypad involves its appearance. To maintain the integrity of the appearance, designers usually design the gap to the minimum size. According to the design specification requirements, the thickness of the silicone rubber keypad is within 2mm, and the minimum gap width should be no less than 0.5mm. The gap width of the silicone product is proportional to the thickness, which means that the thicker the silicone rubber keypad is, the larger the gap width is required.

The gap on the silicone rubber keypad is a rib protruding from the mold, designed to cooperate with the self-disassembly structure. If the gap's width is smaller than the design specification requirements, it will cause the mold to be difficult to process or be damaged due to displacement during mold closing. In addition, if the width of the gap is designed to be too small, it will also make it impossible to self-dissemble the silicone rubber keypad, resulting in an uneven gap, which will affect the appearance.

Minimum thickness of silicone rubber keypad

To meet the necessary structural strength and molding requirements, the minimum thickness of the silicone rubber keypad is generally designed to be no less than 0.5mm. The thickness of the thick part of some blind holes is no less than 0.2mm. Of course, the thickness of the wall of the silicone keypad is an exception.

For the minimum thickness of silicone rubber keypads with conductive pills or conductive carbon oil, the thickness of the conductive silicone rubber keypad within the 1mm range on one side outside the wall should not be less than 1mm. For silicone rubber keypads with combined metal dome or tactile switches at the bottom, the thickness of the base pad should also be less than 0.5mm.

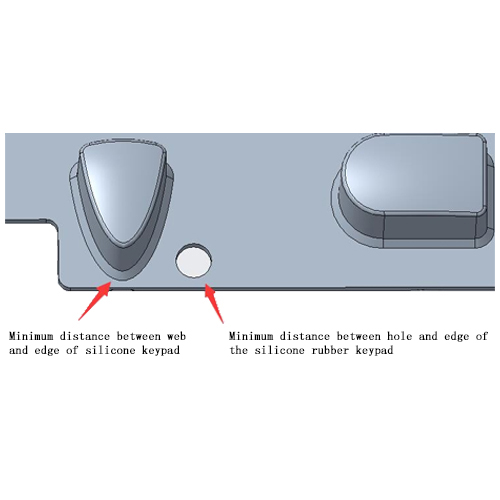

Minimum distance between the web and the edge of silicone rubber keypad

In the design process of silicone rubber keypad structure, the minimum distance between the wall and its surrounding structure is crucial to its feel and service life. To obtain a good feel and long service life, it is generally required that the safety distance between the outermost side of the wall of silicone rubber keypad and the surrounding of the base pad should be no less than 1mm.

Minimum distance between hole and edge of the silicone rubber keypad

To maintain the structural strength around the hole, the distance between the hole of the silicone rubber keypad and its edge should be no less than 1mm. For special structures, the minimum distance should be no less than 0.5mm.

In summary

When designing the structure of a silicone rubber keypad, you must understand and consider its thickness, gap, width, and other structures and follow their minimum size design specifications. If the structure design is unreasonable, it will lead to serious problems including mold processing difficulty, not being opened, easy pressure damage, the product being prone to material shortage, cracking, and difficulty to de-mold. During the R&D and design phase, if you need to understand the design specifications of the silicone rubber keypad structure, please communicate with our professional engineering team to ensure that your silicone project is successfully developed and launched.