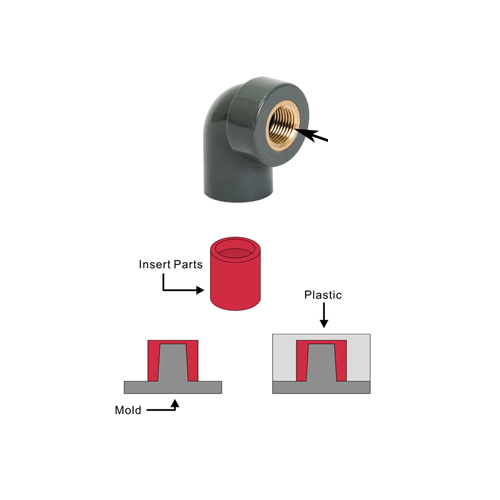

Silicone overmolding is a flexible, efficient, and versatile manufacturing process that offers many advantages over traditional injection molding technology. Yuanyi's silicone overmolding services provide injection molded products in combinations of two or more materials for your project, with a variety of materials to choose from. The quality of incoming materials, mold manufacturing, and mature molding processes enable Yuanyi to provide parts with excellent performance, high precision, and consistency for medical and healthcare, automotive, and maternal and infant applications.

Perhaps you are looking for a reliable manufacturer to provide high-quality parts for your specific project. If you still have questions about the process, design, and materials of silicone overmolding, please contact our professional team immediately. They will quickly provide you with materials and solutions suitable for your project.