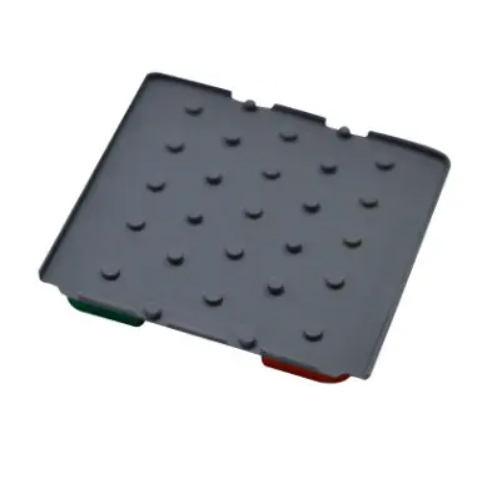

This type of silicone keypad is made of silicone rubber, which has the characteristics of comfortable touch, lightness, not easy to deform, anti-fall, durability, high and low-temperature resistance, aging resistance, and ozone resistance. Due to silicone softness and silkiness, you can feel the softness of the silicone keypad during use which is more suitable for application on mobile devices. To make the surface characters wear-resistant and dirt-resistant, have better light transmittance, and have a long service life, the surface of silicone keypads usually adopts a silk screen printing process. In addition, rubber keypads generally use conductive black particles to achieve a better conductive effect.

Key material: silicone rubber

Color: Original color or customized

Molding process: Silicone compression molding, secondary molding

Surface character technology: Hollow silkscreen

Surface protection layer technology: Touch oil, PU coating, glue, plastic cap

Conductive method: Conductive black particles, conductive ink, metal dome, metal particles, nickel particles

Testing equipment: 3D projector, button elasticity tester, button life tester, alcohol wear tester

Usage: Wireless handheld POS machine, terminal equipment