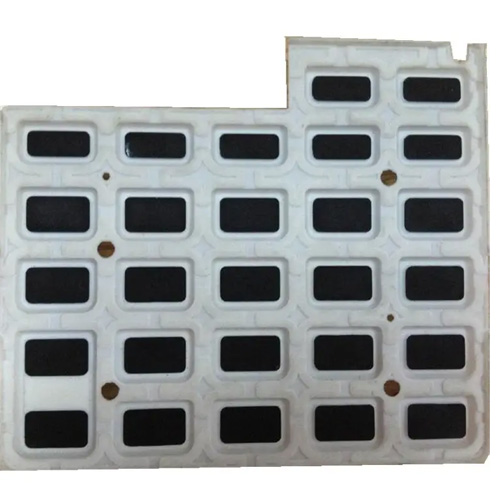

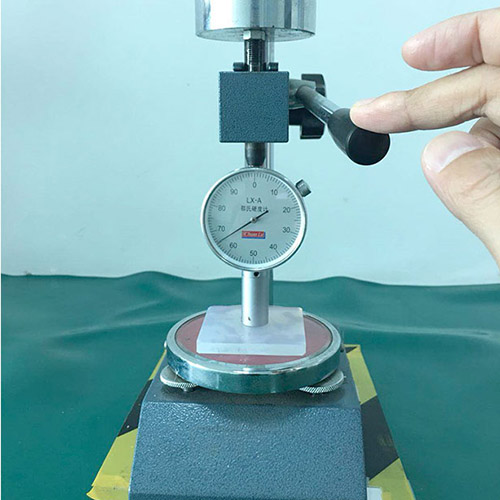

Yuanyi is a manufacturer specializing in automotive silicone keypads. Everything is completed in-house and strictly adheres to the quality management system from product design, rapid prototyping, mass production molds, molding, and post-processing to packaging. Automotive silicone keypads are commonly used silicone rubber products. They are usually made of high-temperature vulcanized silicone rubber (HTV) through silicone compression molding, edge removal, silk screen printing, fuel injection, laser engraving, and other processes. Liquid silicone rubber is sometimes used and is molded by injection injection molding according to design requirements or personal customization. Silicone rubber has good resilience and temperature resistance, while thermoplastic resin has high rigidity and wear resistance. Some automotive silicone keypads are made from a combination of silicone rubber and thermoplastic resin, which combine the properties of the two materials to give them a better feel, durability, and stability. Some automotive silicone keypads are made from a combination of silicone rubber and thermoplastic resin, which combine the properties of the two materials to give them a better feel, durability, and stability